Chemical Industry | Solvent recovery | Determining the end point of a distillation process

The recovery of solvents helps to reduce process costs and protect the environment

Solvents are indispensable in industry as they mix with chemical substances without changing them. They are used in the production of chemical compounds, the control of reactions, surface optimization and separation of substances. Due to their versatility, they are found in large quantities in the chemical and pharmaceutical industries. Their recovery is important both economically and environmentally, which is why corresponding processes are widely used. Distillation is a common method for purifying organic solvents. To ensure product quality, impurities must be measured precisely and the results transmitted directly to the process control system. Together with Hellma Solutions, an online process analytics solution was developed for an international manufacturer of active ingredients.

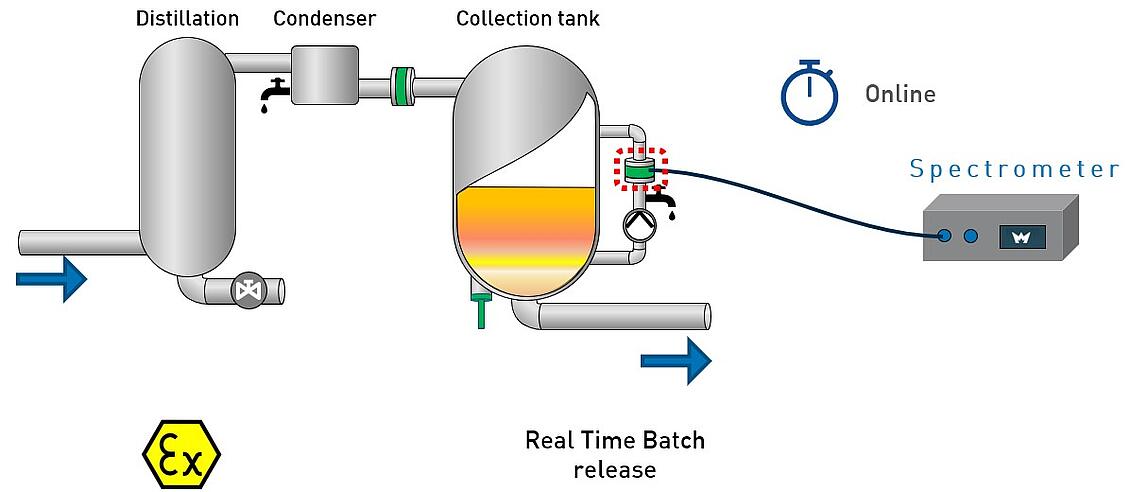

Schematic representation of the online measuring solution

Manufacturers in the chemical and pharmaceutical industry must comply with GMP regulations, which place strict requirements on hygiene, premises, maintenance and calibration of equipment, documentation and traceability of measurement results. They must also ensure that the measurement technology does not compromise product quality and safety.

The guidelines further require that the PAT measurement system, in particular the spectrometer, is compatible with 21 CFR Part 11, which regulates electronic systems in FDA-regulated industries. The measurement interface must contain only FDA-approved materials and must ensure sufficient accuracy in the determination of impurities in the process.

Due to the highly flammable nature of the organic solvent, the measurement technology must also be suitable for use in an ATEX zone 1.

At the end of a distillation process, the end point release is monitored. Various impurities are measured in the process, so far only offline. As part of a joint project, a process analytical technology for this application is being developed and implemented to optimize the process, particularly with regard to compliance with environmental regulations and to save energy and process time. The aim is to improve process control and increase the number of daily batches produced.

A more detailed description on how this application was realized using online measurement technology can be found in our detailed application report, which you can download from the info column at the top of the page.