Driven by rising raw material prices and energy costs, a shortage of skilled workers and high competitive pressure, the chemical industry is constantly exploring potential savings. The continuous monitoring of manufacturing processes by means of process analytics is proving to be particularly useful. Spectroscopic analyses play a major role here, especially for liquid media.

All Advantages at a Glance

Inline Spectroscopy enables the direct identification of ingredients and their quantification. Measurements are performed directly in the medium and often in the process stream under harsh conditions. At this position, you should not make any compromises and build on the best possible reliability.

100 years of experience in molecular spectroscopy

The world' s largest range of probes and measurement cells

Thousands of products sold for various applications since 1994

Online configurator for quick identification of suitable products

It is not possible to say in general terms which products are best used for which application, because this largely depends on individual process conditions.

The following overview gives a rough classification according to installation situation and product characteristics.

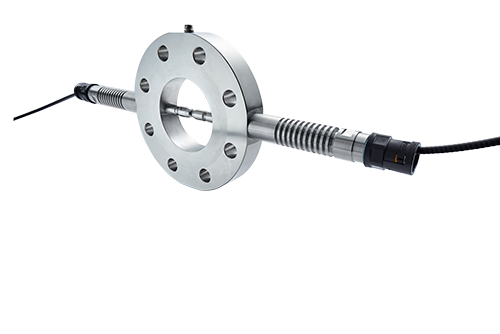

XP = xtremely precise: Elastomer-sealed transmission probe with the best performing measuring head on the market for highly precise and reproducible measurement results.

続ける

HD = heavy duty: Transmission probe with metal seals. Highest robustness in combination with high photometric transmission and accuracy.

続ける

XP = xtremely precise: Ideal for transflectance measurements in transparent and slightly turbid media with high performance measuring head for best measurement results.

続ける

HD = heavy duty: metal-sealed transmission measurement cell for direct installation in pipelines ≥ DN25

続ける

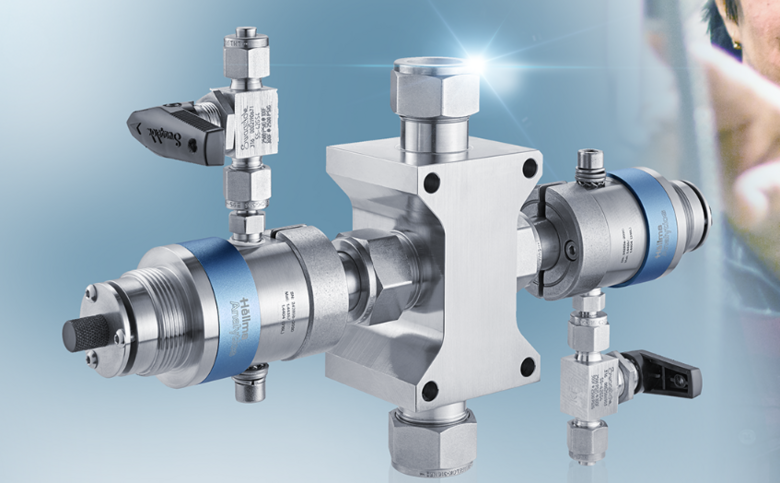

HD = heavy duty: metal-sealed transmission measurement cell with Swagelok fitting, perfectly suited for adverse process conditions.

続ける

HD = heavy duty: transmission measurement cell with extremely robust seal for use at very high pressures, temperatures and viscosity.

続けるRealize up to 16 different measuring points with only one spectrometer and reduce your costs per measuring point significantly!

More information needed?

Probes and measurement cells must be well matched to the pressure, temperature and other process parameters of the application. The online configurator gives you an overview of the product range, shows you what is possible and allows you to quickly and easily select or assemble a product matched to your parameters.

Here are some examples for chemical production processes in which spectroscopic process analytical technology can be beneficial. Talk to us about your application.

We will be happy to advise you on suitable products and solutions.

For the manufacture of coatings, paints and varnishes as well as for many other everyday products, PUR prepolymers with specific properties are used. Through reaction tracking and end-point determination (e.g. using the Falcata XP), NIR spectroscopy ensures that the prepolymer has the desired properties. Good processability, high quality and economical production can thus be ensured.

The manufacturing process of polyurethane using isocyanates involves reactions with phosgene. Due to its toxicity, any (unreacted) phosgene is recovered and remains completely in the manufacturing process without endangering the safety of humans and the environment. By means of NIR spectroscopy, the phosgene content in relevant product streams and storage tanks can be monitored. The second barrier on Hellma HD products reliably prevents leakage. Additional monitoring options for the probes and measurement cells can be implemented on request.

Using NIR spectroscopy, efficient operation of the cracker is ensured in real time. Both the composition of the liquid naphtha (using Hellma FFV) and the gaseous products obtained (using Hellma FCP) are measured and adjusted for this purpose, thus ensuring optimum control of the process and optimal utilization of the raw materials. This not only leads to cost savings but also saves resources, thereby reducing CO2 emissions.

In many processes, solvents are used for production purposes. To save costs and avoid waste, these are recovered. Some of the solvents contain water which can damage plant components through corrosion or, at higher concentrations, even make the solvents unusable for processes. NIR spectroscopy is ideally suited for moisture monitoring. Real-time monitoring can be carried out directly in the product stream or in the respective storage tanks.

The production of personal care products, cleaning agents and detergents, as well as industrial applications, require surface-active substances. One relevant group of these are ethoxylates. The production of ethoxylates by means of ethoxylation of oils from renewable raw materials, for example, requires special care however. The ethylene oxide used in this process must be added in a controlled manner due to its reactivity and must be completely reacted due to its toxic properties. Monitoring the raw materials as well as the ethoxylation reaction in real time, e.g. in loop reactors or stirred vessels, calls for particularly safe components such as the CE-compliant Hellma HD flange.

In the production of resins it is important to produce the most consistent quality possible so as to guarantee the safety and quality of the products made from them, such as adhesives. This is achieved primarily by ensuring the quality of the raw materials and by precise process control during production. Reaction tracking and end-point determination of reactions is performed in real time using NIR spectroscopy together with Excalibur XP and HD transmission probes.

Superabsorbents, such as those used in baby diapers, contain polymers that can bind large amounts of water. Our process probes are used to monitor the production of monomers. In addition to the quality of the measurement results which ensure the highest possible yields of high-quality products, the impermeability and resistance of the materials used are also particularly important.

Additives are used in many manufacturing processes to improve product properties, save costs, or simplify processing. However, these additives can have a detrimental effect on the color of the product. Color analysis by UV/VIS spectroscopy combined with e.g. the Falcata XP can be used to assess the specific changes needed to improve, for example, polymer products. Color analysis not only provides information on color-changing additives, but can also measure molecular changes in stabilizers, fillers, processing aids and antibacterial additives to ensure the targeted product properties.

The Hellma Solutions business division provides integrated analytical solutions from conception to installation. Special feature: Hellma Solutions has a worldwide partner network that can provide a wide variety of instrumentation.

It is only through this flexibility that the metrological concept as well as the instrumentation can be adapted exactly to the requirements of the application. Thus, customers get exactly what they need to solve their measurement task and optimally combine effectiveness with efficiency.