Chemical Industry I Monitoring Critical Process Parameters I Production of Polyols

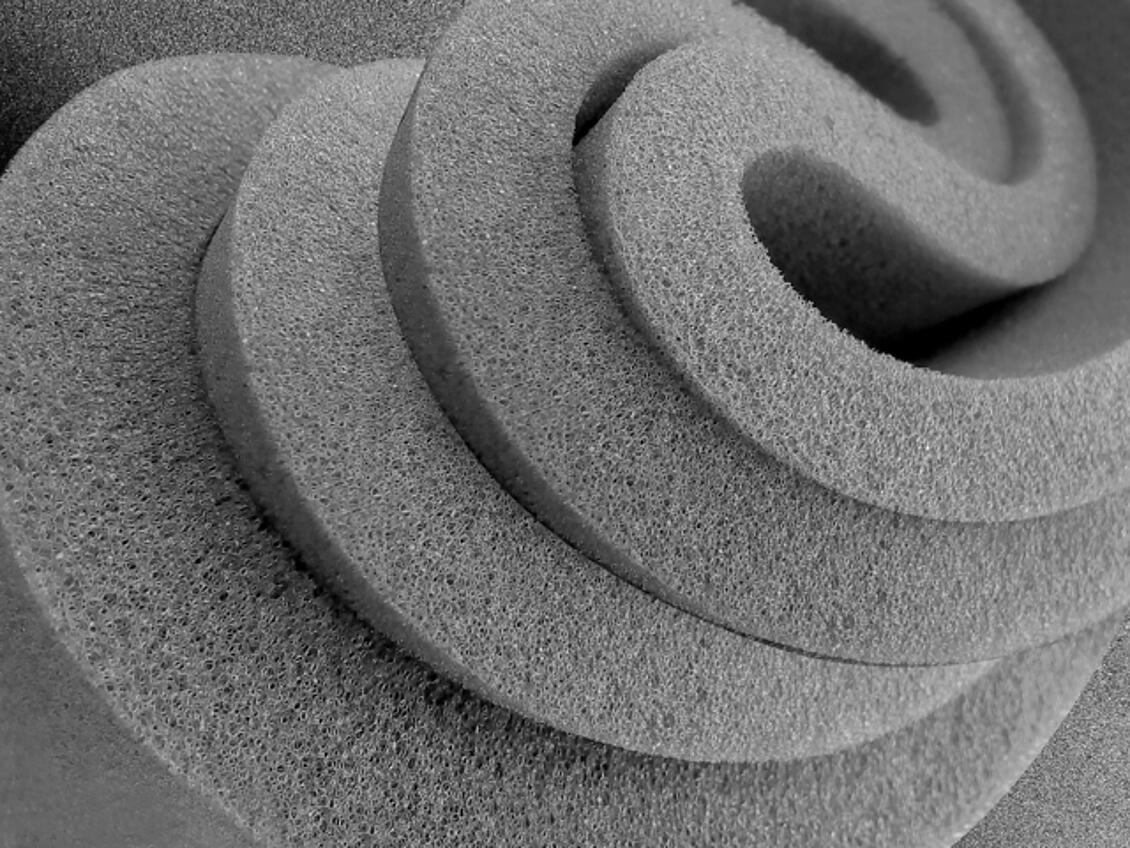

Polyols are essential building blocks of polyurethanes, formed by their reaction with isocyanates. Their chemical versatility enables targeted control of material properties and makes them indispensable for durable and specialized applications. Depending on the raw material base and intended use, polyols can be produced in various forms, for example as foams, adhesives, coatings or elastomers. Their chemical structure largely determines the properties of the end product. The production of polyols is technically demanding, as both their physical characteristics and the complex manufacturing processes pose particular challenges.

The synthesis of polyols requires stable process conditions, as fluctuations in temperature, pressure or reaction time can cause quality deviations. Process interruptions due to measurement failures or deposits must be avoided. In addition, inhomogeneous raw materials or side reactions can cause impurities that manifest themselves in color deviations or uneven viscosity. Conventional sampling in the laboratory is time-consuming and delays the evaluation, which means that deviations can be detected too late and the process cannot be optimally controlled.

The measuring accessories must be designed to work reliably even at temperatures of up to 400°C.

In the production of polyols, various chemical and physical parameters have a significant influence on product quality. In order to detect undesirable side reactions and deviations immediately, these must be monitored continuously and precisely.

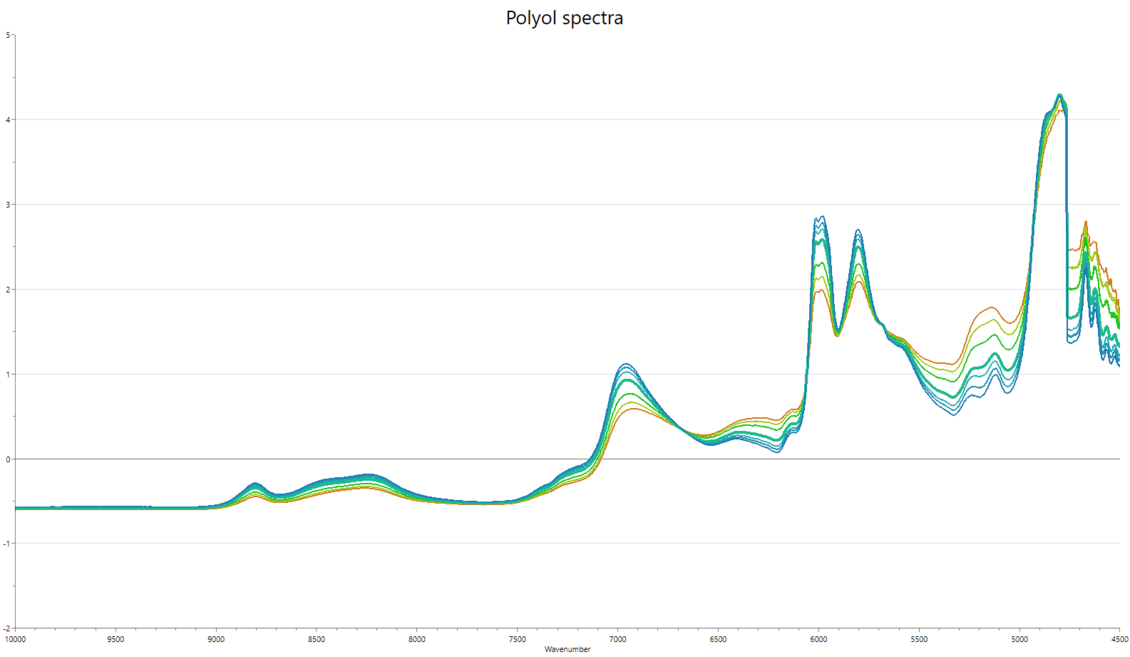

The most important parameters include the water content to control the reactions, the viscosity for the processing properties, the acid number as an indicator of acidic impurities and the hydroxyl number, which determines the reactivity of the product. Traditionally, the quality control of these values is carried out offline in the laboratory, often by titration - a time-consuming process that causes production delays.

Example measurement of the acid number with the Hellma »Excalibur HD FPT«

A more detailed description on how this application was realized using online measurement technology can be found in our detailed application report, which you can download from the info column at the top of the page.