Special Product Advantages

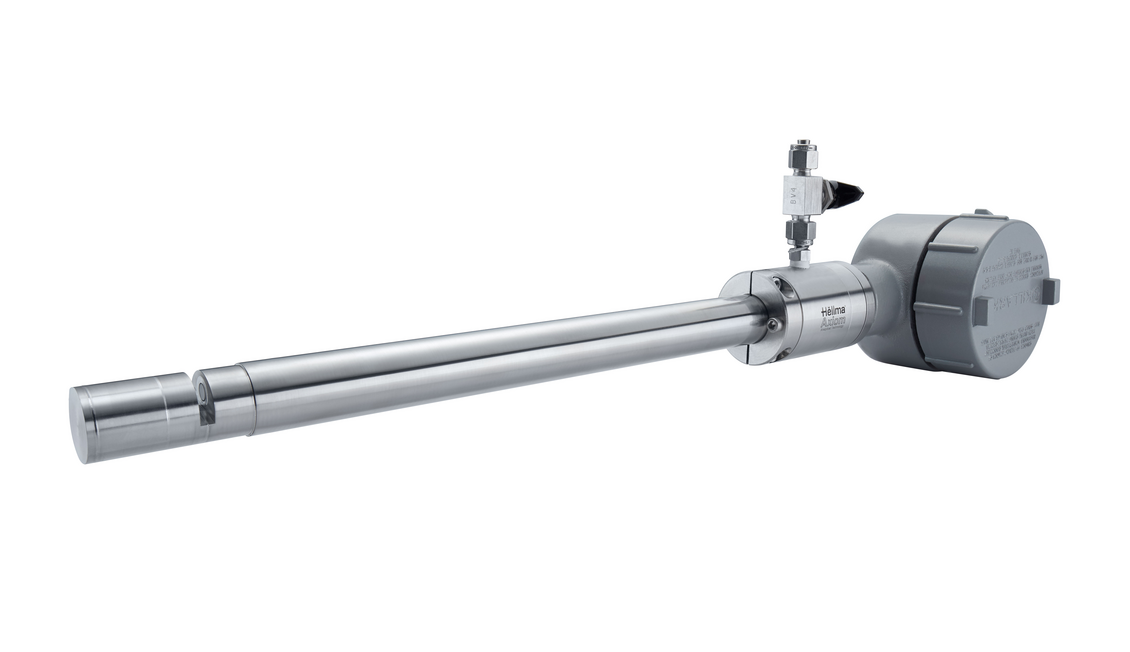

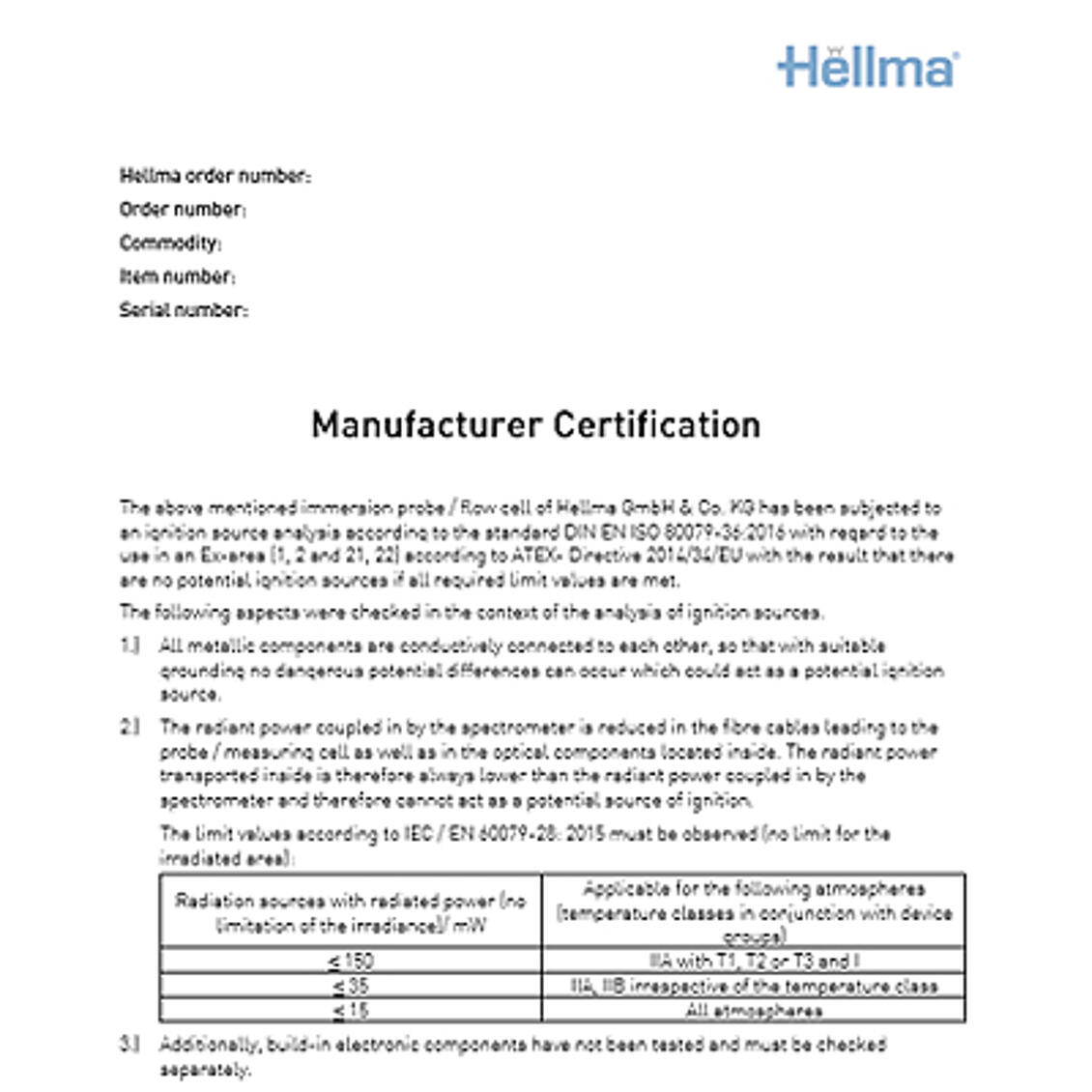

Offers the highest level of security - in every situation

Due to the robust construction with metal sealing and sapphire window, the highest chemical resistance paired with pressure and temperature resistance is guaranteed at all times (compared to O-ring sealed probes). The second barrier on the side facing away from the process reliably prevents product escape and leakage even in extreme situations.

Reliable measurement results without additional operating costs

Even at extremely low temperatures, the use of lightguides and the nitrogen filling in the probe tube means that there is no need for an additional flushing of the iinside of the probe. This eliminates the installation and operating costs that would occur for creating and operating a continuous flush.

Constant measurement results for easy method transfer

Through the use of the latest manufacturing technologies such as electron beam welding and the use of high-precision optical components, we ensure that the FPT probes offer consistently high quality of the measurement results. In addition, a method transfer between individual measuring points is facilitated.