Search

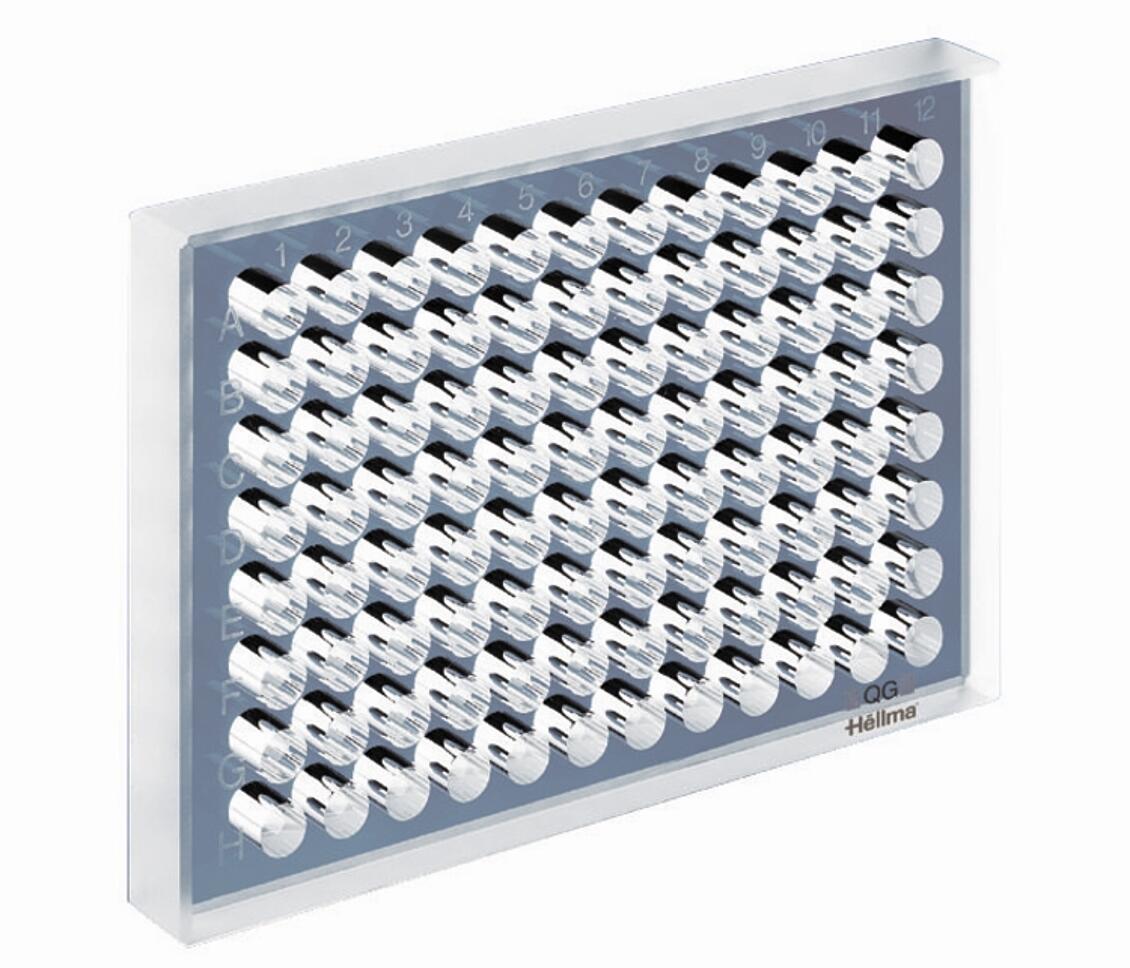

Calibration Standards

Reliable measurement results through regular verification of the spectrometer using certified calibration standards