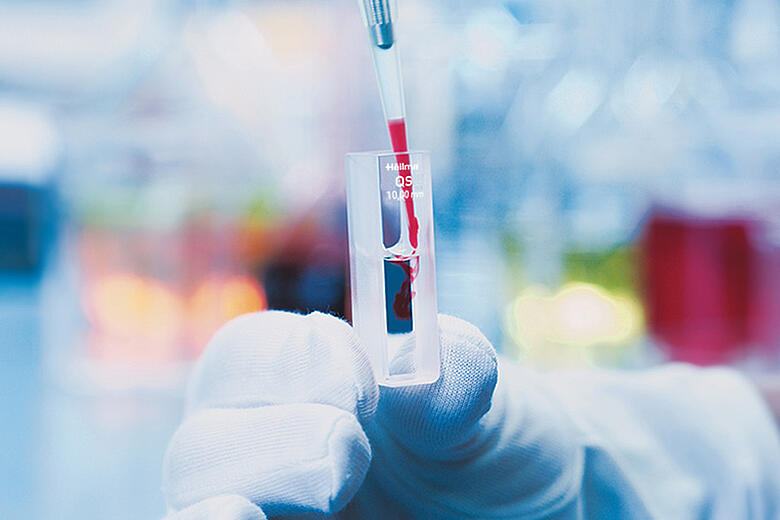

Welcome to Hellma. The world of highest precision!

Hellma is independent provider of integrated solutions for optical analysis and leading manufacturer of high-precision products made of optical glass, quartzglass and crystals. Photonics and molecular spectroscopy customers around the world appreciate Hellma products for their exceptional quality and reliability.

Laboratory Products

Cuvettes, UV/Vis reference materials, micro volume measurement cells, immersion probes, OEM

continue

Process Analytics

The world's largest product portfolio of optical probes and measurement cells - standard products and product configurator

continue

Calibration Laboratory

Recalibration of UV/Vis reference materials based on DIN EN ISO 17025 with calibration certificate

continueVideos

Webinar: Vibrational Spectroscopy and NIR Technology for Polymer Sorting (EN)

European Pharmacopoeia EP 10 | How to comply with the new requirements

polyol production

Online Monitoring of Product-Relevant Parameters in the Production of Polyols

Solvent Receycling

Endpoint Determination of a Distillation Process using NIR Spectroscopy in the Recovery of Solvents

continue

Natural Gas Analysis

Qualitative Analysis of the Composition of Natural Gas Using Raman Spectroscopy

continue