The Measurement Set-Up

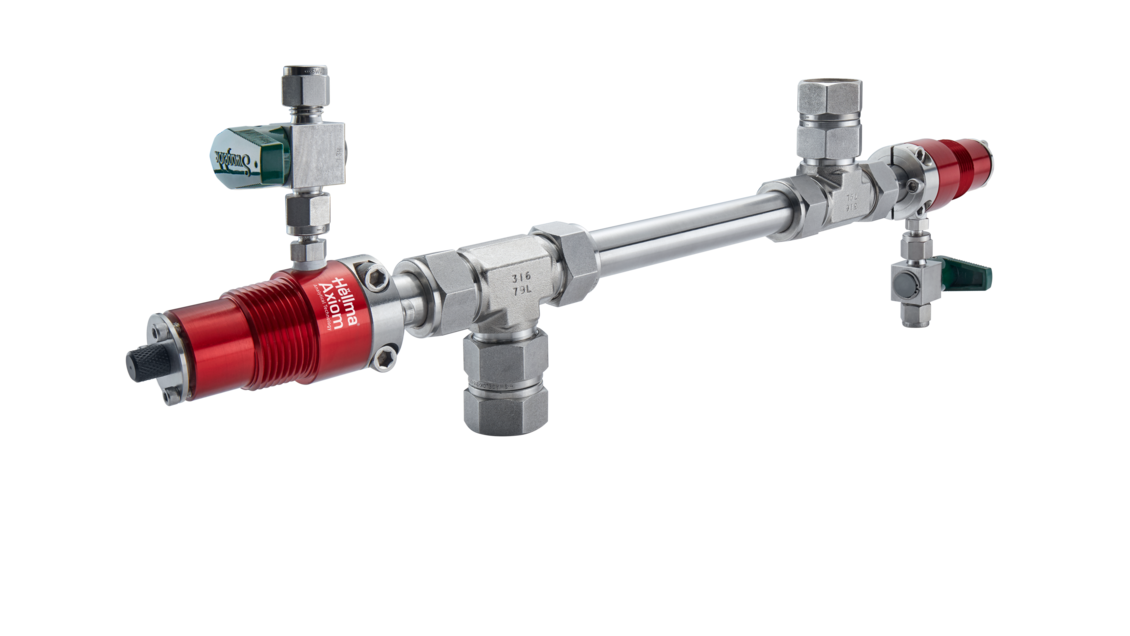

The installation of an online NIR measurement system requires the correct metrological structure and the right combination of measuring principle, location, instrumentation, software and chemometrics. The use of measurement cells or immersion probes enables the direct analysis of large-scale processes. The spectroscopic information is securely transmitted via optical fibers from the cell, over distances of up to 100 m and more, to the measuring instrument. The measurement technology can thus be integrated into the production process and allows for timely monitoring, regulation and intervention to optimize the process. The Hellma Excalibur HD FCP Process Cell is installed inline, connected to a spectrophotometer via fiber optic cables and thus continuously delivers results of the condition of the aqueous saline solution during processing.

The measurement cell must withstand adverse process conditions such as high temperatures and pressures and is therefore made of Hastelloy, which has a high chemical resistance and, depending on the model, is equipped with a removable inspection window for cleaning. The built-in fiber optic cables transmit the spectral information in real time to the NIR spectrometer where the measurement signals are sequentially recorded and evaluated.

Simple Technology – Great Benefit

NIR spectroscopy gives access to a high level of analytical information and simple procedural handling. The NIR spectrum contains a lot of analytically relevant information. The use of NIR spectroscopy results in very short measuring times and both accurate and precise measurement of the materials under process conditions.

This technology makes use of the fact that the quartz glass used in the fiber optic cables has almost no absorption in the NIR range and thus transports the signal without loss even over long distances. With the spectroscopic process data collected in this way, composition and concentration of substances can be identified in real time, while trends and process deviations can be detected immediately. Based on this, process understanding can be significantly improved, the quality of the product can be monitored in a targeted manner and corrective action can be initiated more quickly.