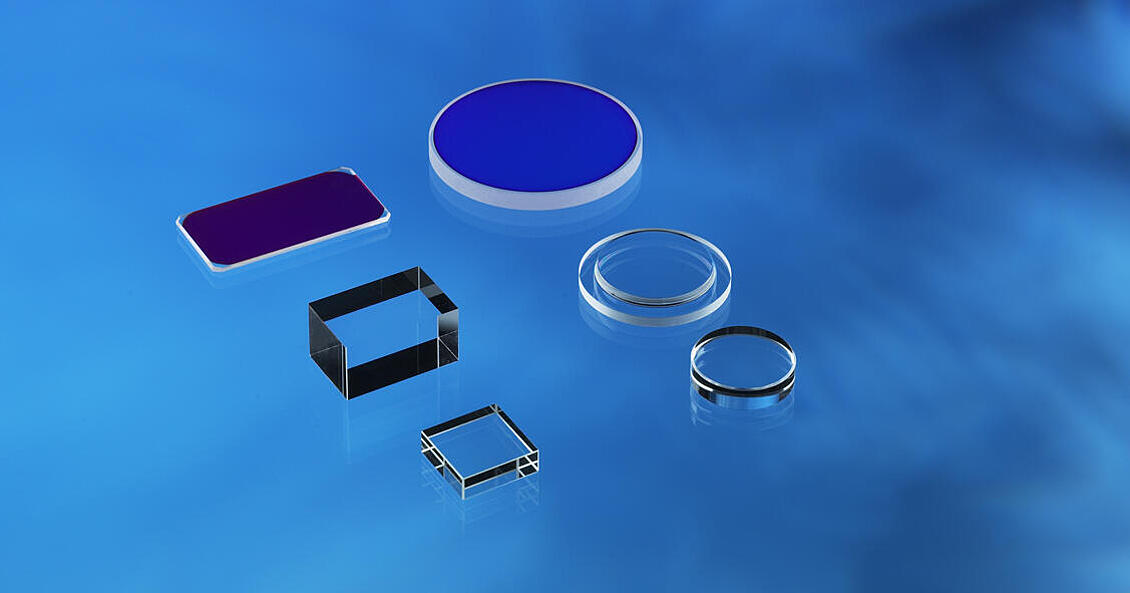

We provide high-grade plano-optical components of up to 800 mm edge length. In order to prevent misunderstandings caused by unclear or incomplete specifications, the required quality and the dimesnions should be precisely defined. The quality of a polished surface is determined by two independent criteria:

- The freedom from surface faults as specified under DIN-ISO 10110-7.

- A value for the planarity of a surface, which specifies the amount of registration error according to DIN-ISO 10110-5 (PV or RMS value).

An extremely important value is the permissible wavefront deformation with optical windows, because that takes into account the influence of both glass faces involved, giving an indication of the planarity of the two faces and their mutual parallelism obsolete. In this case, window thickness is solely dictated by mechanical criteria and the tolerances can be selected with correspondingly broadened values. Wavefront deformation also occurs with wedge plates and prisms in a similar fashion.

Required coatings can be applied to plano-optical components on request.

Basically, flat optics can be manufactured from all types of glass that are listed in the two catalogs: “SCHOTT Optical Glass” and “SCHOTT Optical Glass Filters” as well as the quartz glass types from SCHOTT AG, Heraeus, SCHOTT BOROFLOAT®, SCHOTT Zerodur®, DESAG B 270 and equivalent materials of other manufacturers. Even crystalline materials can be processed (with few exceptions).